Yesterday I inspected the house, and Kunihara-san explained to me the work he has done in the two weeks of my absence.

The main room looks essentially the same as before, however the wall in the middle is now filled with cellulose. And the flooring is covered with boards for protection.

The kitchen is now complete, and we only need to finish the walls and add the centre kitchen, furniture and fridge.

The bedrooms are also complete, with only the window frames waiting to be filled with double glazing. Please note that we only use 4 star boards, that are from sustainable forestry production.

This shows the corridor behind the kitchen, were toilet and bathroom are located. Kunihara-san, closed off the end of the corridor, so that we can add a wash basin.

And finally the exit to the Kura (store-house) was permanently sealed, to comply with building regulations. From now on we must access it from outside.

Wednesday 30 April 2008

Carpentry nearly finished

Posted by

Patrick:

1 comments

![]()

Labels: carpenter, finishing, insulation, kunihara

Summer already?

Golden week approaches, and it feels like summer in Ueda. The town is as always ready for a party, and they organised a little festival in front of the station to celebrate golden week.

Taiko drums set the the tone, and this was followed up by Pro-Wrestling guys wearing silly masks. They also had a bouncy castle and various food stalls.

Tulips that we planted last autumn are now also in bloom, very much to the joy of my little daughter who was my assistant on this trip.

In Arisaka village, people were also in a festive mood, and decorated the river with carps for the boys (kodomo-no-hi).

Posted by

Patrick:

0

comments

![]()

Labels: arisaka, festival, summer, ueda station

Cellulose Blow-In Insulation

After some forward and backward, we decided to use environmental friendly cellulose for insulation. The stuff is basically made out of recycled newspapers, with the addition of fire retarding borates, a naturally occurring salt that is harmless to human health and the environment.

In this case we do not need to put insulation material before attaching the membrane, but the other way round: The membrane is added first and sealed, and then the blow-in machine's tube is inserted into a small hole cut for this purpose. The contractor then feeds the cellulose packs into a machine that shreds it and then blows the fibres into the cavity. After the cavity is filled up, the hole is sealed with a tape.

The advantage of this approach is that even the uneven walls, beams and posts can be packed in tightly with insulation material.

This shows one of the bedrooms being prepared for the blow-in contractor.

This is the outside of the house, now including the new window frames. and a new wall segment.

The living room is regarded as relatively "cold" because of the window-front, and the bed-rooms are therefore insulated from it.

Posted by

Patrick:

0

comments

![]()

Labels: blow-in, insulation, Intello

Intello Demonstration

Sorry I only come to write about it a few weeks later.

A German Meister was sent by Proclima to Japan, to demonstrate the use of the Intello membrane and its installation to contractors, architects and consultants.

Kunihara-san prepared a wooden frame in the kitchen, to put some insulation material.

For the purpose of the demonstration we used wool/synthetic mix fleeces. Later on we actually replaced them with a more suitable material.

The insulation material is then covered with the Intello membrane which is stapled on about every 10cm.

The edges are fixed airtight with a special glue that is applied like silicone, but unlike the latter does not dry out. The membrane is installed overlapping, and this edge is then sealed with special tape. The glue only works on porous surfaces like wood, so the tape is also used for window frames out of aluminum, or other non-absorbing materials.

It was a very short two days, but I learned a lot about insulation and air-tightness in buildings. When actually applying the membrane its easy to notice that it must already be considered at the design stage, to avoid too many protruding fixtures, that have to be taped off in a time consuming manner. Great care must be taken, even with electricity cables, for which very special tapes sealers exist.

once in place, the room can be sealed totally air-tight and so offers the best insulation possible, while the natural insulation materials covered by it are kept rot and mildew free.

Posted by

Patrick:

0

comments

![]()

Labels: eco membrane, Intello, Meister, proclima

Monday 7 April 2008

German Meister in Arisaka

In a previous post I already mentioned the eco membrane "intello" from the German "Proclima". We now had a German Meister for two days at our house, to give instruction on how to use and install the membrane properly.

He was able to stay with a Yanagisawa-san, a very kind local who together with his wife agreed to put up with him for two nights.

I will write more about the demonstration later, but it was very enjoyable for everyone to talk about each other's customs and way of living. Of course we also introduced Thomas (the Meister) to Japanese Hotspring, and he particularly enjoyed the massage/torture chair. However, he could not be pursuaded to eat sashimi, and other lovely fish products.

As he was from Weinheim, I was able to coomunicate with him in our native "Badisch", so I actually ended up interpreting Badisch and Japanese!

Posted by

Patrick:

0

comments

![]()

Labels: Intello, Meister, Onsen, Yanagisawa

Flooring preparation

After the weak beams and post have been replaced, Kunihara-san put up some speed and is now working towards the flooring preparation.

First let's look at the repair work of last time from a bit closer. The view is much better after the scaffolding is removed, and you can see the four beautiful wood pieces fitting together neatly.

This photo shows an extension joint - two wood pieces have been put together without any kind of nail or other metal piece.

This shows how the concrete bases work: at the time they were poured, it was ensured that they are level, and now it is much easier to place the framework for the flooring on top.

This shows again the main room with all bases, and framework complete.

Here a floor insulation panel is cut to size and ready to be inserted into the framework.

Kunihara Junior, follows up by taping the seams of the panels, so that the floor becomes airtight, a precondition for heating and cooling efficiency.

Posted by

Patrick:

0

comments

![]()

Labels: airtight, carpenter, flooring, frame work, insulation, join

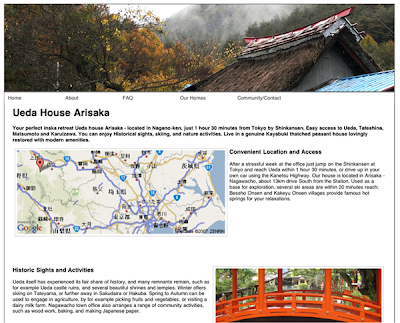

Website enhanced

Our website (http://www.inakahome.com) was greatly improved by the addition of several sections. Of course, regular readers of our blog will not find any specifically new information, but it makes a better impression to first time visitors. We will next add a Japanese version within the following weeks. Please be patient with the "make reservation NOW" button - we must finish the house first ;-)

Posted by

Patrick:

0

comments

![]()

Labels: website